How To Avoid Damp, Wet, Leaky Basements. A Guide to Waterproofing Your Basement with HDPE & SBS Membrane

by Babu George

Originally published on May 29, 2024, 8:49 pm, updated on November 12, 2025

scroll downYogiraj, was relieved and excited when he finalized the purchase of a new commercial building in Kochi, the business capital of Kerala. He has just returned from Middle East and wanted to settled in Kerala with his life’s earnings to start a new business. Brimming with joy he had visions of a thriving business filled his mind, and the expansive basement seemed like the perfect place for parking, additional storage or even a future expansion. Summer was in full swing, and the basement appeared dry and promising.

Fast forward to monsoon season. The relentless rains brought a rude awakening. Yogiraj, descending to his basement with a hopeful spring in his step, was met with a scene of utter dismay – a layer of water glistening ominously across the concrete floor. The dream of a dry, usable space has vanished and had turned into a watery nightmare.

Yogiraj’s story is, unfortunately, all too common. Many new buildings, especially those constructed in dry weather, often skip crucial waterproofing steps during construction. This seemingly minor oversight can have major consequences, as Yogiraj discovered. The monsoon rains exposed a fundamental flaw – the basement lacked a proper waterproofing system, leaving it vulnerable to water intrusion.

While a damp basement can feel like a sudden and unwelcome guest, the reality is that these issues often stem from a missed opportunity during the construction phase: neglecting to waterproof the basement during its initial construction. This seemingly minor oversight can have far-reaching consequences, impacting not just the functionality and aesthetics of your basement but also the structural integrity of your entire home.

Not Planning to Waterproof your Basement?

A water flooded basement | ©UniPro Waterproofing

Here’s a closer look at the problems that can arise from skipping basement waterproofing during construction:

-

Moisture Intrusion:

This is the most obvious and immediate consequence. Basements are naturally susceptible to water intrusion from various sources, including high groundwater levels, poor drainage around the foundation, and even cracks in the foundation walls. Without a proper waterproofing system, this water can easily seep into the basement, leading to a damp and potentially mouldy environment.

-

Structural Damage:

Water is no friend to concrete foundations. Over time, constant moisture exposure can weaken the foundation, corrode reinforcement steels, leading to cracks, bowing walls, and even foundation failure. These structural problems can be incredibly expensive to repair and can significantly compromise the overall value and safety of your home.

-

Health Concerns:

Mould thrives in damp environments, and a leaky basement can quickly become a breeding ground for this harmful fungus. Mould exposure can trigger respiratory problems, allergies, and other health issues for residents, particularly those with sensitivities.

-

Reduced Functionality:

A damp basement is simply unusable. The presence of moisture makes it impossible to store belongings safely or create a comfortable living space. You lose out on valuable square footage that could be transformed into a home gym, playroom, or additional living area.

-

Decreased Property Value:

A leaky basement is a major turn-off for potential buyers. Not only does it raise concerns about structural integrity and habitability, but it also signals the need for expensive repairs. A damp basement can significantly decrease the resale value of your home.

A Water flooded Basement | ©UniPro Waterproofing

By prioritizing basement waterproofing during construction, you can prevent these problems before they even have a chance to start. This proactive approach not only saves you money on down-the-line repairs but also protects the structural integrity and value of your home, while creating a dry and healthy environment for your family.

Damp walls, dripping water, and a general sense of despair – these are the hallmarks of a basement plagued by moisture/leak problems. But with a little extra effort and precaution during the construction, you can avoid this unpleasant situation in your basements/cellars and continue using them as a usable and valuable part of your living area.

This guide delves into the world of basement waterproofing, specifically focusing on a revolutionary system built with High-Density Polyethylene (HDPE) Membrane. With the right approach, you can say goodbye to a wet basement and hello to a dry, finished space ready for your needs. Read on to know more.

The Problem: Why Waterproof Your Basement?

Basements are susceptible to water intrusion for several reasons. High groundwater levels, poor drainage around the foundation, and cracks in the grade slabs, retaining walls etc can all contribute to a damp, flooded basement and potentially mouldy environment. Left unchecked, water damage can lead to a host of problems, from structural deterioration to health concerns as mentioned above.

The Solution: Introducing the revolutionary HDPE Membrane & SBS Membrane

HDPE Membranes

HDPE Membrane Rolls

HDPE Membranes offers a powerful and innovative approach to basement waterproofing. This material boasts exceptional strength, flexibility, and puncture resistance, making it ideal for creating a watertight barrier against moisture intrusion. HDPE membranes are designed to shield your concrete from water, water vapor, and aggressive ground salts, gas and chemicals by fully bonding to the raft/grade on slab. This inert material is resistant to chemicals, acids, bases, and salts, offering excellent long-term corrosion resistance.

Benefits of Using HDPE Membranes:

-

Superior Bonding:

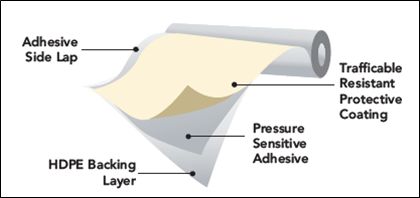

Components of HDPE Membrane

Pre-applied pressure-sensitive adhesive ensures a strong, lasting bond with poured concrete, even in case of settling. Joined with Double-sided tapes on edges or joints, HDPE Membrane forms a complete watertight seal between the below substrate and the upper RCC/concrete layer. Continuous bond to poured concrete means membranes are unaffected by ground settlement.

-

Durable and Protective:

Manufactured from high-density polyethylene, HDPE membranes are designed to provide Fully adhered watertight laps and detailing to shield your concrete from water, water vapor, and aggressive ground salts, gas and chemicals. This inert material is resistant to chemicals, acids, bases, and salts, offering excellent long-term corrosion resistance.

-

Unmatched Performance:

Pressure Sensitive Granules of HDPE Membrane

Unlike traditional membranes, HDPE forms a monolithic bond with wet concrete, eliminating the risk of water tracking between the membrane and the structure. The continuous adhesive bond ensures a complete barrier to water, moisture, and gas, while also providing puncture resistance during construction.

-

Simple and quick Installation:

The installation process for HDPE membrane is relatively quick and efficient can be placed even directly over properly prepared compacted soil. Also, it requires no priming on surfaces properly prepared following surface preparation requirements. It Allows for foot traffic immediately after application. System is ready for immediate placing of reinforcing steel.

-

Superior Strength, Chemical resistance and Durability:

Does not activate prematurely during construction. Provides a barrier to water, moisture and gas – physically isolates the structure from the surrounding ground. It protects structure from salt and sulphate attack, effective in most types of soils and water.

-

More Usable Space:

Can be applied to permanent formwork like plywood etc- maximizes use of confined sites where set back is not available

-

Impermeable:

Perm rating less than 0.1 Perms.

-

Solar reflective:

Reduced temperature gain during construction.

HDPE Membranes: Wide Range of Applications:

HDPE membranes are a versatile solution for various waterproofing needs, including:

- Basements

- Podiums

- Parking Areas

- Retention Walls

- RC Members

- Tunnels, Underpasses & Culverts

- Water Retaining Structures

- Sewage Treatment Plants

- Underground Metro Stations

- Service Rooms

- Pier & Harbour Protection

SBS Membranes:

SBS Membrane Application on a Sump tank Walls | ©UniPro Waterproofing

Tailored for Retaining Walls & Pile Head Dressing SBS, or Styrene-Butadiene-Styrene, membranes are another powerful tool in our waterproofing arsenal.

Advantages of Using SBS Membranes:

These self-adhesive membranes offer distinct advantages for specific applications.

-

Strength of with HDPE lining:

Cold applied self-adhesive waterproofing membrane based on SBS modified bitumen. The bitumen compound is laminated onto an impervious, non-perforated, high performance cross laminated HDPE film. The membrane is protected on the self-adhesive side with a release film. This membrane is used as waterproofing/ damp proofing layer over harden concrete by using bitumen primer.

-

Fully Bonded:

SBS membranes create a strong, seamless bond with the substrate, ensuring long-lasting waterproofing.

-

Ideal for Retaining Walls:

SBS membranes excel in applications like retaining walls due to their ability to conform to complex shapes and uneven surfaces.

-

Cost-Effective and Durable:

SBS offers a cost-effective solution while delivering long-lasting performance.

-

Flexibility, Strength & Lasting Protection Over Time:

Even after years of exposure, SBS membranes retain their elasticity and pliability, ensuring continued protection. It also offers good temperature resistance to cold and warm temperatures with high tensile strength, tear and puncture resistance.

SBS Membranes – Areas of Application:

SBS membranes are a great choice for waterproofing a variety of structures, including:

- Roofing

- Foundation Walls

- Underground Structures

- Curtain Walls

- Basement Walls

- Balconies

- Terrace Roofs

- Inclined/Pitch Roofs

- Water Tanks

- Manmade Ponds

The Process: How is HDPE & SBS Membranes Installed?

Here’s a breakdown of the key steps involved in waterproofing your basement with HDPE membrane:

-

Base Preparation:

This crucial step ensures a solid and stable foundation for the membrane. Uneven surfaces and gaps need to be addressed to create a smooth and level base. Grouting around utility lines adds stability, and depending on the existing substructure, additional preparation might be required.

-

Laying the Membrane:

HDPE Membrane being laid in a basement area before reinforcement steel work

The HDPE membrane itself is strategically placed with the High-Density Polyethylene (HDPE) side facing the substrate and the textured layer facing upwards. Unlike traditional membranes, HDPE forms a strong bond with the wet concrete poured over it, becoming an integral part of the structure. This eliminates the risk of water finding its way between the membrane and the concrete.

-

Creating a Seamless Seal:

HDPE Membrane laid with 75mm Overlaps | ©UniPro Waterproofing

Overlapping seams are essential for a watertight barrier. Each sheet of membrane must be meticulously positioned to overlap the previous sheet by 75mm along the designated selvedge. Cleanliness is paramount – ensure the overlapping area is free of debris before creating a continuous, crease-free bond using a heavy roller.

-

Securing Roll Ends and Cut Edges:

Similar to seam overlaps, roll ends and cut edges require meticulous attention. A minimum 75mm overlap is necessary, and the area should be clean and free of contamination. Special double-sided tape comes into play here, ensuring a complete and secure bond between the membrane and the substrate.

-

Pile Cap/Pile Head Treatment:

Pile Head treatment with SBS Membrane | ©UniPro Waterproofing

For basements with foundation piles, specific measures are taken around the pile heads. The area is treated with a suitable bitumen primer before carefully placing the HDPE membrane around the external circumference. Additional layers of SBS membrane are applied to create a comprehensive watertight seal.

-

Concrete Pouring:

The concrete can be poured within 42 days of applying the membrane. During this process, caution is necessary when vibrating the concrete to avoid damaging the waterproofing materials.

-

Temporary Protection & Inspection Procedures:

If the subsequent activities are getting delayed beyond 14 days on the HDPE Membrane applied areas, temporarily protect the membrane with plastic sheets, the areas where the subsequent application are to be carried out should be thoroughly inspected on completion of a specific area before placing any reinforcing steel. Any damage to the membrane system should be made good using DS Tape or oversize patching with HDPE Membrane.

SBS Membrane Installation Process:

- Post necessary surface preparation, primer application is the first step. Inspect the surface conditions. The concrete surface should be levelled, tough and should not have hollow areas or pot holes. Check hollowness by hammering and repair such areas as well as pot holes using polymer modified cementitious mortar (PMM). Allow it to cure for 72 hours before application of the membrane. Clean surface so that it is free from loose dust, particles, oil etc. using broom/brush.

Bitumen primer application before SBS Membrane application | ©UniPro Waterproofing

- Apply suitable bitumen primer as per manufacturer’s specification over the vertical surface before membrane application. Allow it to dry for 4-6 hrs.

- Unroll the membrane and align with proper marking all over the area. Re roll the roll into its original form so that alignment is not disturbed. Peel off the release film from the self-adhesive side and start unrolling the membrane and press it to the surface.

- Smoothen the membrane from the centre of the edges by pressing in order to remove entrapped air. Keep the overlap margin of minimum 100 mm between two adjoining membranes.

- Laying of the membrane will be done in such a manner that the roll’s alignment does not get disturbed. Use a strong roller against the applied membrane to ensure proper and strong bonding with the primed surface.

SBS Membrane applied on a under ground water tank | ©UniPro Waterproofing

- For side overlaps a minimum of 50 mm and for the end overlaps 100 mm should be ensured. Use a strong roller against the applied membrane to ensure a proper and strong bonding with the primed surface.

- Protection: The membrane needs to be protected by HDPE dimple boards or any other means.

Dimple Board fixed as protection before backfilling | ©UniPro Waterproofing

- Back Fill: It is recommended to back fill the retaining wall with sandy soil, or sandy gravel, since water passes through this material easily, and it tends to compact to meet the structural requirements, this will need to be determined by a geotechnical engineer and if the load is critical, it is better to refill layer by layer by compacting with water so that it doesn’t settle after filling.

Consider Professional Installation

While the steps outlined above provide a general overview, it’s important to acknowledge the complexity of basement waterproofing projects. Professional installation by experienced contractors ensures the job is done correctly, maximizing the effectiveness of the HDPE membrane and protecting your investment.

A damp basement can be a major headache. However, with the innovative technology of HDPE membrane, you can transform your basement into a dry, usable space. By understanding the process and the benefits of this system, you can make an informed decision about waterproofing your basement and creating a valuable addition to your home. Remember, for optimal results, consider consulting with a professional waterproofing contractor to discuss your specific needs and ensure a successful outcome.

Don’t let water win the battle! Contact UniPro® Waterproofing today and discover how our state-of-the-art HDPE and SBS membranes can provide lasting peace of mind for your basements, cellars, or retaining walls.

※※※